![]()

Ready-to-eat lasagna

![]()

Ready-to-eat cannelloni

![]()

Double pasteurization

![]()

Stabilization

![]()

Freezing process

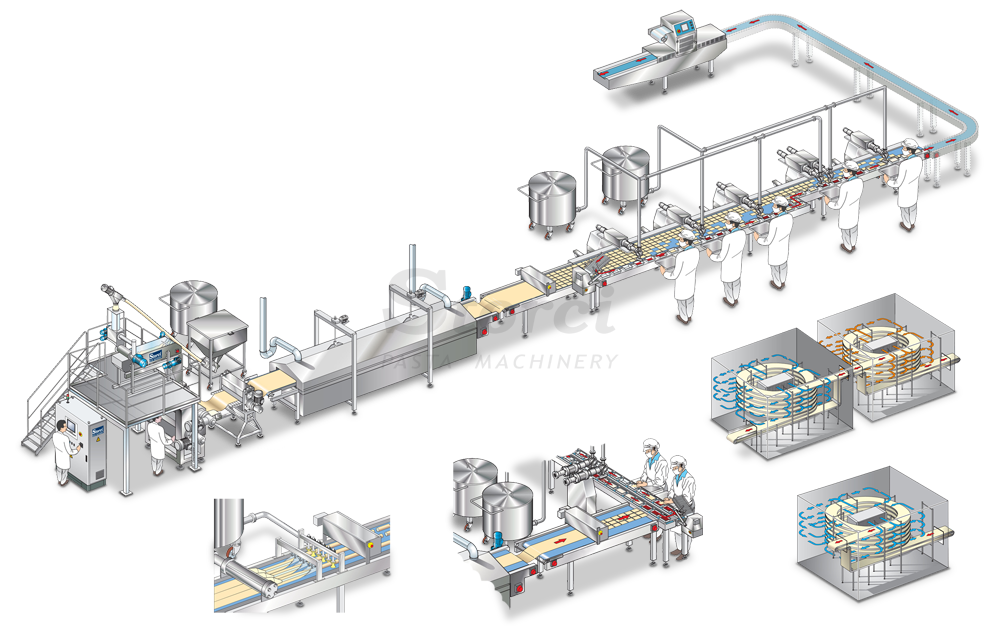

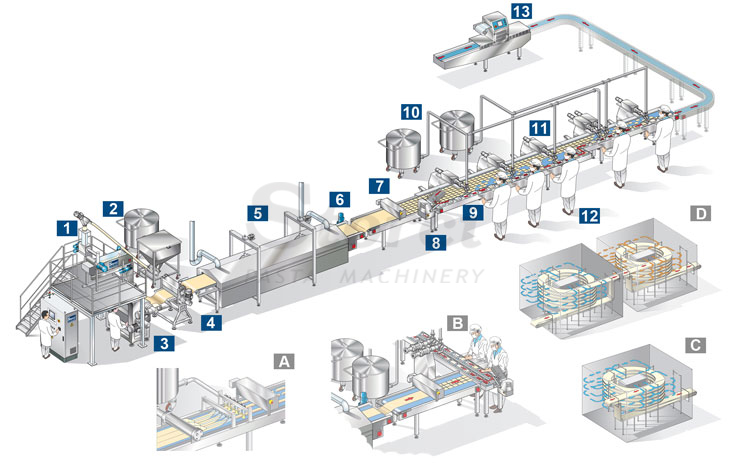

Having the best technology for a quality dough has never been so easy: the automatic total vacuum press assures that pasta holds up to cooking. The lines have been designed and created with a special attention to the cleanliness and hygiene of each detail. They can be revolving lines with configuration ranging from 1200 to 2400 trays/hour. The number and position of the dosing devices - for sauces, condiments, grated cheese - depend on the recipe. They are suitable for hot manufacturing and great capacities. There is also the option for the application of shaping, filling and precooked filled cannelloni groups. This is an innovative technology and a cutting-edge solution for both performance and operating costs.

Play the video

Thanks to our lines: simple management, first level automations for high quality products; easy cleaning and total vacuum technology to get a yellow dough that stays firm after cooking.

![]()

The lasagna and cannelloni line (capacity ranging from 1200 to 2440 trays per hour) can be customized according to your needs. Several options are available that make it suitable for any requirements.

We have stored all the information that you can find in this page, together with other useful tips, in a easily readable document. Download our brochure clicking here below. You will need Adobe Reader.