You can set up your line according to your specific needs. Optional components are available to make this line very well-performing still respectful of the tradition, for an excellent couscous.

This is a strongly recommended option, especially when the pasta factory is not airconditioned and jumps in temperature might produce condensation inside the scraps circuit. In this case we can offer an anti-condensation circuit, that is none other than a heating circuit, that is employed along the scraps recovery route, particularly at the piping bends. It avoids doing extra maintenance, mould formation or similar formations as well as activation of the line stop made in order to remove the product obstructing the pipe itself.

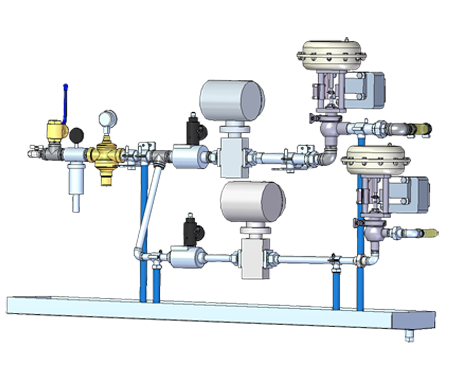

Thanks to this option you can dose the water optimising the quantity needed for the powders, the fine and coarse couscous, that need different quantity of water.

This kit helps regulate the couscous production, for both the hourly capacity and different grinds: coarse, medium and fine.

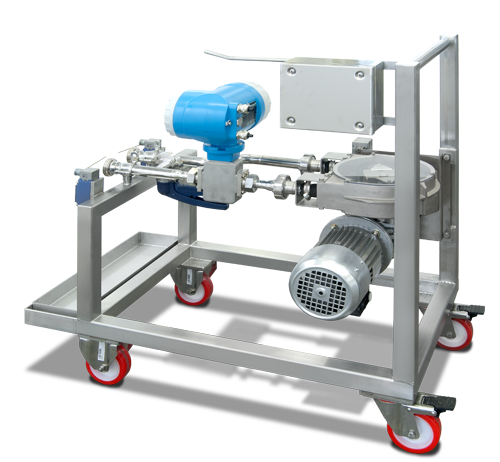

Do you have additives for your couscous? We have all the necessary systems for you. Reliability, sanitizability, dosage precision, safety and simplicity. This group of options, all wheeled, arise from the need for supplying an alternative to the ingredients dosed in the presses, compared to powder dosage.

The storage and mixture of the additives with water takes place in the tanks. A couple of tanks are usually offered along with a dosing pump to safeguard the production and guarantee the times reduction, since one can be used during the dosage phase and the other one remains at disposal for preparing another mixture. The capacity can vary depending on modifications such as the press hourly production. The tank, ready with the product to be mixed, is placed near the press together with the pump (to which is joined by a flexible pipe).

Dosing pumps are available in several models (with lobes, peristaltic pumps, etc) depending on the type of plant. The pump is equipped with a capacity measurer handling the pump speed, thus enabling an optimal dosage.

Automatic cleaning system of the additives plant by C.I.P. Compact group for the cleaning of piping and additives dosing plants, strongly recommended with egg dosage (due to its bacteriological degree of severity). Hence in this case the sanitizing process must be monitored periodically for each part in contact with the product, by C.I.P. group.

Whenever you have to dose solid additives such as spinach, powdered eggs, tomatoes, turmeric, vitamins, etc., you can resort to solid additives dosing group. The choice might lie between a doser with one screw or with two screws (with small capacities or when the products stick to each other) You could also opt for either a volumetric doser ( for non-hygroscopic raw materials such as flour or semolina) or a gravimetric one (for products such as tomatoes, vitamins, etc). Both can be fed manually or automatically, according to the Customer’s needs.

Grazie a questo optional, che è un misuratore di portata, è possibile regolare la quantità e la qualità di vapore utilizzato. E' utile sia dal punto di vista "tecnologico" (mantiene costante la quantità di vapore utilizzato) sia dal punto di vista del controllo del consumo. Il vapore in eccesso (che cioè non occorre per la cottura del prodotto) viene aspirato, dalla testa alla coda della macchina, e poi espulso tramite un ventilatore.

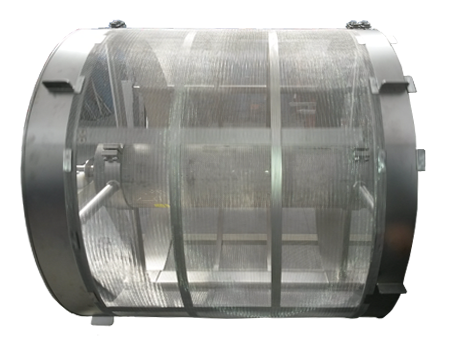

Thanks to this option, you can recover all the powders of the plant, including the volatile ones that come from the line settling cyclones. This way powders are drawn, from any place where they can be formed, by Ciclofan system, preventing their deposit onto the machines and around the factory.