Dry pasta is a distinctive product of Italian enterprise. It is easy to produce, widely consumed and allows a start-up to grow quickly, event exporting abroad. If you are on this page, you probably know all this and just want to examine in depth how to manufacture short and long dry pasta. Now we are going to analyse all the situations each entrepreneur might face to make his Company grow or to open a new business, as follows:

Pasta drying process consists in thermally treating the fresh product to make pasta dehydrate till a residual humidity of 12%, thus complying with law. The initial mixing, made of semolina and water, must have a humidity of about 30%. The water added to the semolina during the process helps the product to become malleable, so that it can be shaped as desired.

This simple introduction belongs to the traditions of each of us; it becomes more complex on the base of the capacities and times of production.

A good pasta maker, as well as a good entrepreneur, knows how to weigh up times, quantity and quality of his product..

The machines and ingredients necessary to the production are always the same but may vary for capacities reasons.

The most important machine is undoubtedly the press. In the press, semolina and water are mixed together and afterwards the dough is transformed in a shape of pasta. The dough is pushed through a die, usually made of bronze, that gives shape to the pasta. Later, a circular blade cuts it according to the desired length. The capacity of production of the press establishes the dimensions of a pasta factory. All the machines following the press must have capacities such to match the press.

Once pasta is shaped like tortiglioni, penne, fusilli, spaghetti…is deposited onto trays for short pasta or sticks for long pasta. These two phases can have different levels of automation according to quantity and pasta maker’s needs. The larger the capacities, the more automations should be considered, both for logistics and personnel reduction costs.

Long pasta extrusion head: here spaghetti come from.

We have thus made the pasta and laid it onto trays or sticks for the drying phase. The drying phase is a thermal treatment by which the humidity of the product decreases from 30% to 12%, possibly in less than 12 hours (so that a double daily working swift is possible). It is indeed a very strong treatment that can jeopardize the success of the most delicate shapes such as spaghetti. To reduce the drying times and make the product more resistant, it is necessary a pre-drying phase. The pasta maker calls it “preincartata”.

We are ready now to proceed to the drying phase. In the artisan pasta-factories the drying is always static. The pasta is positioned inside the dryers for a time ranging from 8 to 12 hours approximately. Th drying bend is set by the pasta maker and is established so that pasta is dehydrated homogeneously from its core to the external part. This is the phase when a pasta maker puts into practice all his experience.

After drying, the residual humidity at 12% is verified by a sample check and the 3-year expiration date can be certified on the label. At this point, the packaging phase is missing, but we will talk about it later on.

Find out how Pastificio Marulo Srl manufactures excellent dry pasta in Gragnano with our machinery

A dry pasta making factory is, for all intents and purposes, a company. When thinking over the production and sale of pasta, it comes immediately to mind that the subjects to be assessed are really many. We can try to analyse them in this guide, although, due to the complexity of the issue, we invite you to contact us for a thorough investigation.

Training starts just from the very first visit to a factory and basically never ends. Once analysed your expectations, we will visit a customer of ours who has the same kind of plant. We will see in detail the machines in operation, their dimensions, the handling of the goods; we will follow the entire logical process from the semolina to the packaging of the finished product. Once the plant has been built, in addition to the test technician, we provide the services our technologist in charge of the new projects. We will monitor your activity both in person and remotely. With your consent, thanks to our IoT staff, we will be able to intervene with our technicians without being physically present on site, enter your drying programs and assist you, always, wherever you are. You will also have at your disposal our Training Center (a real pasta factory with our lines installed and not a simulation laboratory) and our R&D Lab. In both, you will be able to carry out production tests and / or professional training, with the full cooperation of our experts.

What frightens more is the easiest thing to do. Apart from a normal drinking water supplying system and the possibility of being reached by the electricity network, there is nothing else to hinder the construction of the system. You just send us the .dwg file of the floor plan and our technicians will provide you with all the useful instructions for masonry work and connections. Just engage any construction company. About six months after the order confirmation, we will come to install your complete dry pasta line.

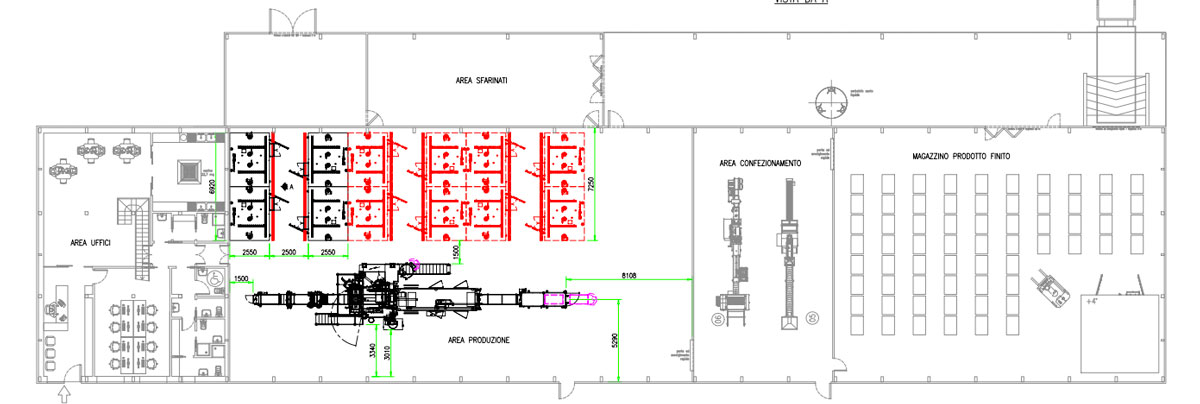

Example of an automatic short and long pasta line plant with (from left to right) entrance, office area, changing rooms. Production area with production plant and dryers. Above, raw material storage area. Central area intended for packaging. On the right the finished product storage and shipping area.

The Fourth Industrial Revolution (or Industry 4.0) is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology. The Internet of things (IoT), improved communication and selfmonitoring, that can analyze and diagnose issues without the need for human intervention, is integrated in this process. Thanks to this system, in case of need, our technicians can intervene without being physically on the spot and the company can monitor each situation, like the alarms status and the production phase. We have also created specific working stations, undergoing further evolution, to give remote technical assistance to the Customer with the help of detectors and webcams, Storci staff can pilot the technician of the pasta factory, wherever he is. For more information watch the video!

There are really a lot of companies producing packaging systems all over the world. There is no specific sector for the packaging of pasta. Rather, there are machines that are also suitable for packaging pasta but which are often also used by pharmaceutical companies, small mechanical parts retailers and much more. What really matters in packaging is the "packaging" in its communicative meaning. Packaging is now considered the fifth "c" of marketing (the 4 C of marketing) and this is particularly true in the pasta sector. Observing any pasta shelf in a shopping center we immediately realize its importance and attractive power. Instead of looking for packaging machines, you should look for a clever graphic designer!

Assistance Guarantee and Safety are three aspects of a plant that are usually set aside a little by the evaluations of an entrepreneur. By assistance, it is intended to be able to receive spare parts in a very short time. Every day without a spare part is a day without production. One day less turnover.

More info about our Service Spare parts and overhauls.

The warranty keeps us safe from unforeseen expenses. Especially if we are far away from the supplier company, it is important to have an extended warranty well beyond the legal requirements.

Never approach a supplier company that does not comply, even stubbornly, with all safety regulations. Pasta machines work at enormous pressures and have a high level of automation with great technology in motion. Safety is an ethical duty rather than a legal one.

As entrepreneurs, we will necessarily have to build a network of contacts that can help us follow all those activities related to our company although not representing its core business. In the first place:

A food analysis laboratory should be selected. To find the one closest to you, guarantying its professionalism, it is advisable to consult the website of the Ministry of Labor. Here you will find the complete list of analysis laboratories that can draw up your haccp manual and help you navigate the labyrinth of Italian legislation, and above all certify sample analyses inside the factory.

Before using your own capital, it is always advisable to seek advice from a company specializing in financing. Be careful, we are not talking about accountants, but real service companies specialized in the study of regulations related to grant awards. They also deal with the preparation of the necessary docs. Their reward is a percentage of the funds eventually obtained.

"No wind is in favor of the sailor who does not know where to go (Seneca)" - Seneca

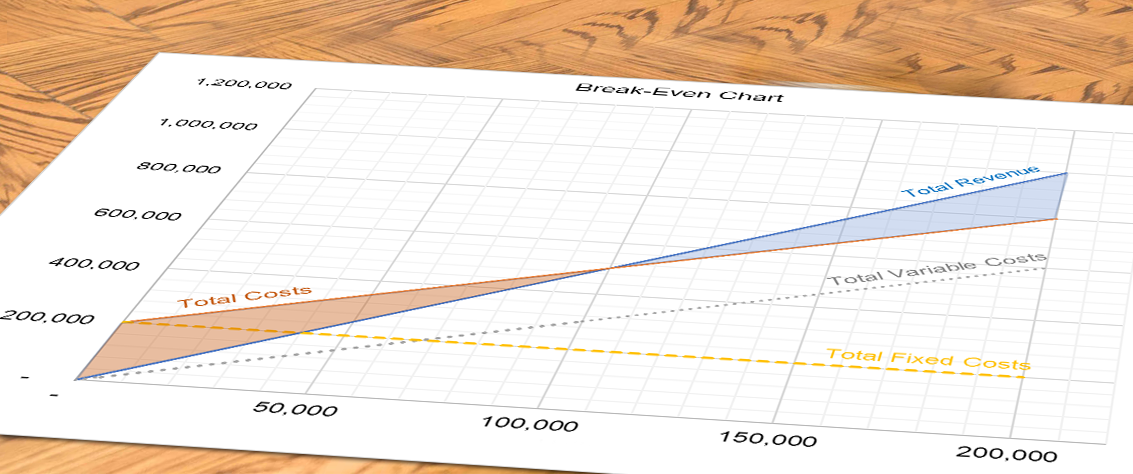

The business plan is an important moment in the decision-making process for starting any business. It is the tool with which processes, procedures, roles, costs and revenues are defined. The business plan is nothing more than the "feasibility" analysis of a project. Feasibility can be distinguished in three parts, as in the following sections.

It basically represents the training background of the aspiring entrepreneur. If we want, in a nutshell, his CV. For example, my chances of success in opening a pasta factory will certainly increase if I come from a similar company if not from a pasta factory , from a farm or other food company; or, alternatively, having attended courses related to this sector.

By external feasibility we mean the market analysis of the competition. Balance sheets, size, growth and above all price lists are analysed of representative sample of about ten companies. The outcome is the maximum price that the market is willing to spend on that product.

We have to assess both the organization of processes and production costs, considering personnel, raw material and processing costs. Knowing the costs, we now have a minimum and a maximum sales price limit not to be exceeded to make our pricing policy.

Example of breakeven point analyses.

Email us, we are here for you.

We are also present in the USA to provide you with assistance and support for all requests and needs.

Storci S.p.A.

246 NW Plaza Dr., Riverside, MO 64150, United States

Since 1991 we have been working in the pasta machinery sector, in the pursuit of technology and innovation, making sure that the right attention is always given to tradition. Our team consists of active and expert professionals, set in a lively and versatile organization, operating with a sole aim: Customers' satisfaction. Whether it be engineers, technologists, mechanics, designers, customer service...our staff always make sure that the possible Buyer can fully reach his goal. We guarantee expertise and a great cooperation. Although it is no longer a family-run business, due to the great growth of the past few years, the Company has been keeping up its original philosophy as its main feature, towards both its Partners, thanks to a successful cooperation, exchange of views and mutual trust, and especially its Customers. This attitude also applies to the people working in the Company and we continuously pay attention to training and refresher courses, because we are aware of the appreciation of each individual and of the positive outcome this has on the whole team.

Strada Lemignano 6, a Lemignano di Collecchio, Parma - CAP 43044

ITALIA