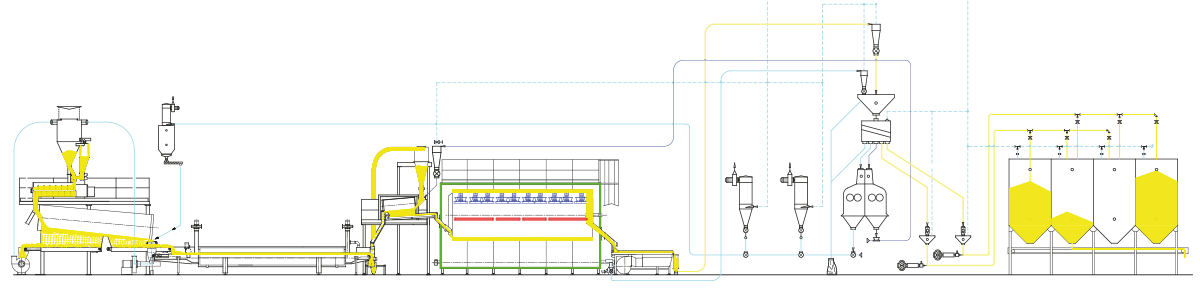

CC Functional diagram

Couscous is a natural product dating back to an ancient tradition that requires care and expertise to be formed and cooked in compliance with the standards required to make it a healthy and enjoyable food. For this reason, we have dedicated all our experience to create a line capable of providing the best product possible at each stage of the process. All the technical and design know-how acquired by our company over 80 years of activity have been transferred to this process. The technology adopted strictly and scientifically implements the standards imposed by this food. Particular attention is paid to those details that determine higher performances and maximizing product quality based on the raw materials used.

The hydration and cohesion system and the method of recovery of the recycled product have been the subject of substantial improvements precisely because they are fundamental for the classification of the couscous.

The forming unit, the Rouleuse, is easily adaptable through interchangeable meshes to optimize the formation of the required grain size. The cooking phase is very accurate in order to obtain thorough and uniform cooking of the product, by injecting the steam above and below the product. Even the conveyor belt can be easily cleaned. Another qualifying point is the original sieving/sifting method (screening) of the couscous before it enters the dryer. This unique and revolutionary system ensures that all lump formations larger than the diameter of the desired couscous are automatically conveyed to the crusher.

As a result, drying becomes a somewhat easier and more uniform process. The rotary drum dryer is ideal for this product and the type of ventilation applied maximizes the dryer’s efficiency levels. The product is easily dried requiring a quantity of energy directly proportional to the uniformly evaporated mass.

The vibratory fluid-type bed cooler that follows the dryer has an optimal performance rate. It can, in fact, by using ambient air, convey the couscous to the sieves or mill at a suitable temperature for the following phases.

The classification/selection, milling and filtering system has a limited job to do because the couscous, at the end of the process, has similar dimensions to the average-sized grain demanded on the market. The less milling carried out on the product, the less dust generated and the brighter the product, not to mention the much improved efficiency rates. These are the improvements that have been integrated to our couscous line, the characteristics of which can be seen in the following photo gallery.

The innovative electronic supervision system is intuitive and easy to use and ensures that you can run the line and all production cycle phases in a flexible and reliable manner. It integrates perfectly with the pasta factory control system to guarantee the exchange of all process data necessary for production control and product traceability.

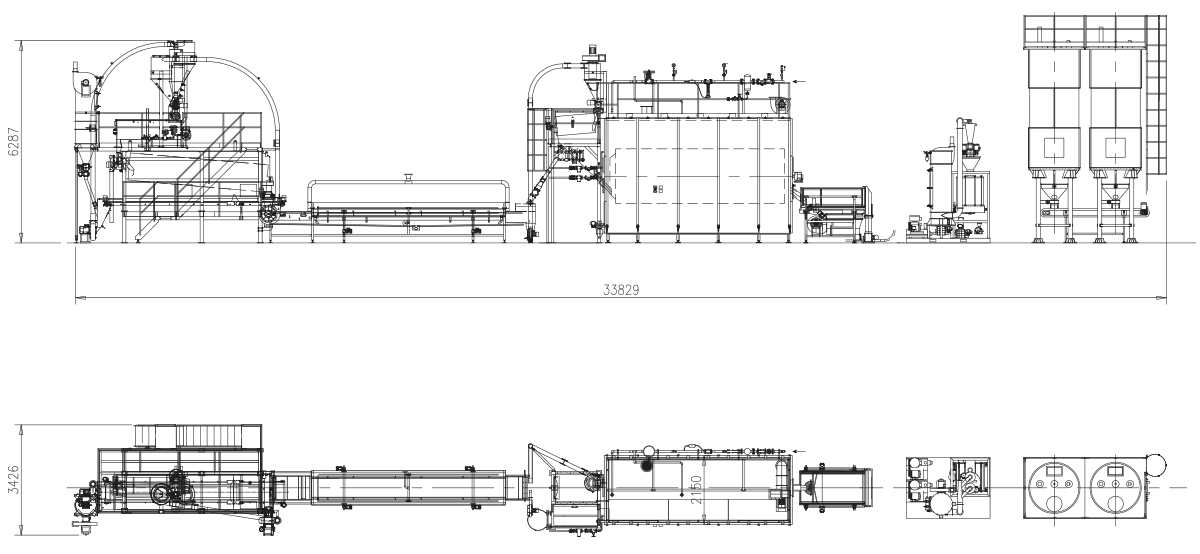

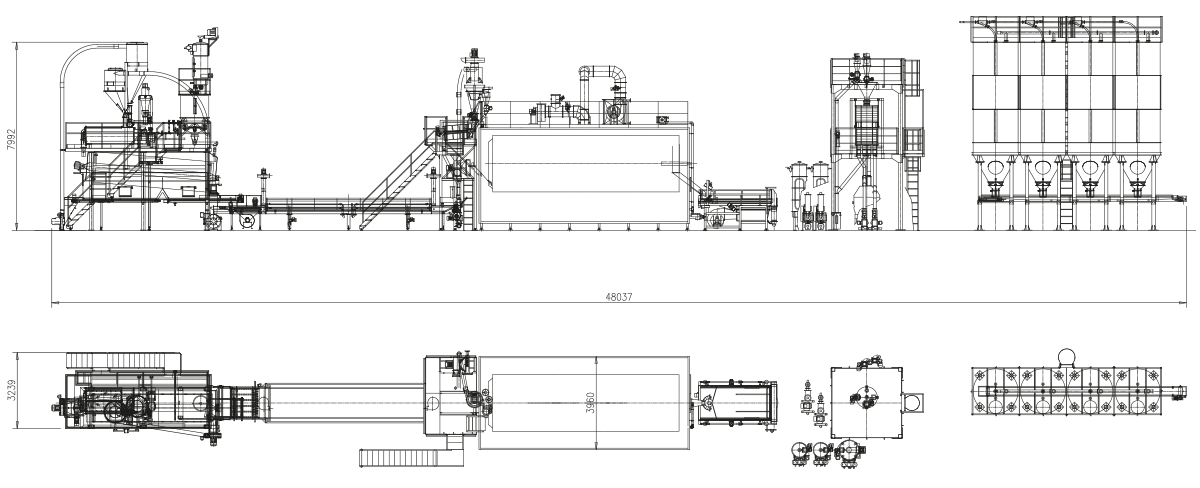

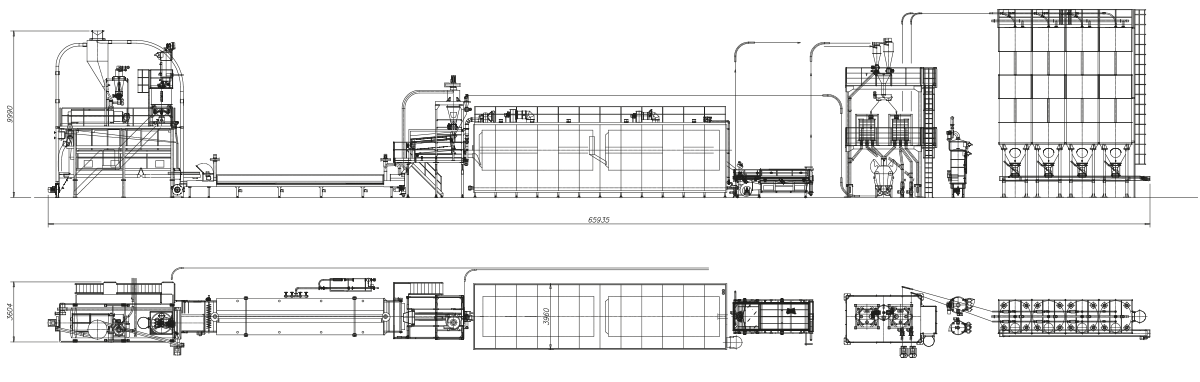

| Capacity Kg/h | Forming Unit | Cooker | Dryer | Cooler |

|---|---|---|---|---|

| 600 | IMP/CC + ROULOUSE 600 | CVS-600/CC | ROMET HT 10/6 CC V | RAA 1000x2000 |

| 1200 | IMP/CC + ROULOUSE 1200 | CVS-1200/CC | ROMET DV 24/9 CC V | RAA 1500x3000 |

| 2400 | IMP/CC + ROULOUSE 2400 | CVS-2400/CC | ROMET HT 24/6,5/2 CC | RAA 1500x5000 |

+39 051 68 43 411