In our nests and lasagna line you can find all the technologies that have made us world leaders for decades. Either your production is small or large, these technologies will give you great results.

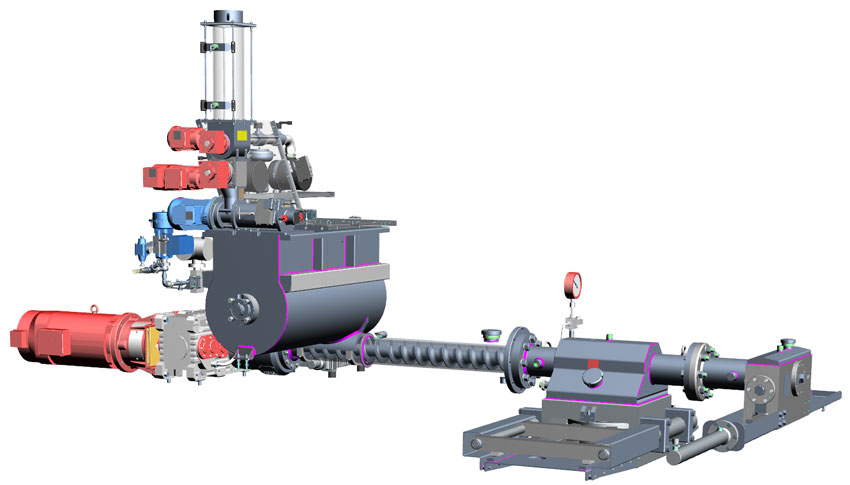

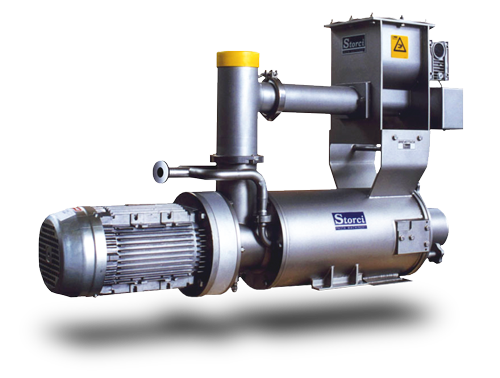

Our presses are made of first choice long-lasting materials. They are created to work non-stop for weeks, with no pauses. You can choose between the total vacuum technology or, with optional Beltmix, a slow kneading technology to get a very high quality final product.

Thanks to the total vacuum technology, we can get a vivid colour dough with excellent organoleptic features. This technology enables you to produce high quality pasta limiting the costs and the dimensions of the plants.

Made of first choice materials and attentively designed. Our presses are reliable, resilient, long-lasting and performing. They are assembled on the largest production plants in the world, where no error is permitted. No wonder that the biggest pasta press in the world, able to produce 12.000kg/h, is a Storci press. The guarantee extendible up to 5 years is a proof of our presses reliability.

This technology enhances the result thanks to longer kneading times that enable to obtain higher quality pasta and brighter colours; production monitoring with product changes, more efficient cleaning and hygiene are also guaranteed. Moreover, an energy saving ranging from 10 to 30 times compared to the traditional tank: up to € 21.000 saving per year, for a 3000 kg/h line.

Our worldwide patented Premix® is the best system in the market for pre-kneading. Resulting from our long experience in this sector, it can produce large quantities of dough with low energy costs, high quality result and it does not need operators.

Premix® pre-hydrates flours independently. It works continuously and produces large quantities of dough with no need of operators.

Thanks to our patented technology, Premix® prepares the dough perfectly mixing water and flours and any other additive, with exact hydration times. Without warming the dough. The result is the best possible at the moment.

It reduces the production costs thanks to very low consumptions, cleaning ease and speed and to total automatic functioning. It can produce approximately 1000 kg of dough using just one kW.

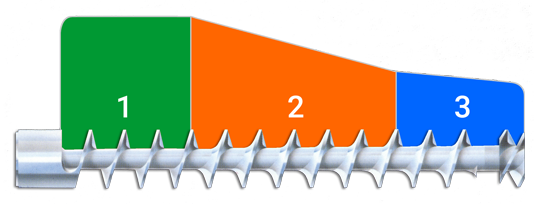

Thanks to their state-of-the-art configuration, Storci compression screws enable to get top quality results with a remarkable energy saving.

We have been producing compression screws for over 30 years, for Customers from all over the world, ranging from the artisanal pasta factories in Gragnano to large industrial ones. All these years of research, development and uninterrupted improvements guarantee for unrivalled performances.

We select the best materials to make our compression screws. Stainless steel, tempered and mirror polished by the most advanced technology. The least possible friction for the dough. Easier to clean and more long-lasting, to give you the greatest possible reliability.

For over 30 years we have been working on the screws optimisation and the effect that it has on dough quality. Our latest generation screws can reduce the dough temperature keeping higher the gluten value and consequently increasing the hold up to cooking. The design of our compression screws has been maximised during the years up to reaching a unique quality level. Not only do they respect the mixture guaranteeing a better end result, but they can also reduce the energy waste, giving you back day by day a significant economy saving.

Our circular heads are the result of over 60-year experience. Our technology enables you to reduce the heating up of the mixture to the minimum, enhancing the organoleptic qualities of the pasta and making the head cleaning an easy job.

Our heads are long-lasting , reliable and made of the best materials.They can also be made of stainless steel, can be easily sanitised and conform to USDA standards.

Our heads range from a minimum diameter of 150mm up to 220, 300, 350, 400, 460, 520, reaching 670mm. Choose that one that suits your needs. Storci produces heads that can extrude pasta with a capacity of about 3000 kg/h.

Thanks to Storci’s sanitization technology, head cleaning is so easy. These heads and their related cutting groups, have been created to be disassembled and easily sanitized, also by pression washing. Moreover, the die change process has been made extremely safe, so that incidents are prevented.

Thanks to our technology you can produce nests or lasagna or both. Advanced technical solutions and a strong frame: all this has enabled us to produce nests and lasagne machines easy to clean and with a reduced maintenance management.

Thanks to our machine you can choose to produce laminated pasta or drawn pasta. You can set up the dough thickness and the tagliatelle width from 1,5 to 16mm. More sizes are available upon request. It is available with 8 or 16 pipes, with a production capacity reaching 250 kg/h for the first case and 500 kg/h for the latter one.

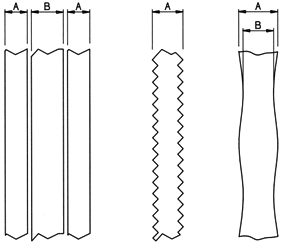

Our technology enables you to get a wide range of shapes,such as the festooned shape (see above, central drawing) available by means of a die (like reginette). You can also get the “varied” or the “wavy” shape (see above, left and right drawings), starting with the lamination phase.

Thanks to several set-ups, you can have a wide range of surface finishing so that your product stands out from the others. Marbled or coarse-grained (see pics on the left), choose the finishing type and start your production, our machinery will do the rest.

Pre-dryer for nests and lasagne – Predryer – enables you to carry out the pre-dryer phase that is so important . especially when producing nests, because it improves the product final shape. Moreover, its modulating structure can find the right balance between the air drawn inside and the humidity level in the different areas of the tunnel.

In our pre-dryer we have included a hot air external pre-ventilation area and inside it the fans hit the nest with a first air blow . This ensures the nests typical perfect shape.

This machine strong point is the modularization. Indeed, it is possible to choose its length, according to the humidity level you would like to reach. The tunnel is composed of blocks; there are usually two/three areas according to the length. Inside the tunnel there is a series of hot water fed batteries and a series of fans placed over and under the trays feeding system; the roof consists of air exchange valves and fans extracting the humidity coming out of the pasta. Temperature and humidity are set up by PLC.

The pre-drying phase helps quickening the drying that will take place in the static cell, after the product exiting the tunnel, to obtain a perfectly dried product.

The drying takes place in programmable static cells that can dry every kind of pasta, so that you can produce all the shapes you like, simply selecting them from the menu. The more increases the production, the more cells you can add, making the investment modular, with no squanders.

Moving from long pasta to short pasta drying is as simple as touching your smartphone. The touch-screen interface lets you change recipe and settings in a handful of seconds.

Storci’s drying system is modular. When increasing your production, you can add more cells to dry larger quantities of pasta. Low starting investment with unlimited chances of growth, with no squanders.

Our drying cells for dry pasta are installed in over 30 countries worldwide. The guarantee is extended up to 10 years for walls (only for fiberglass version) and puts them among the most reliable on the market. As usual, our technology is at your disposal.