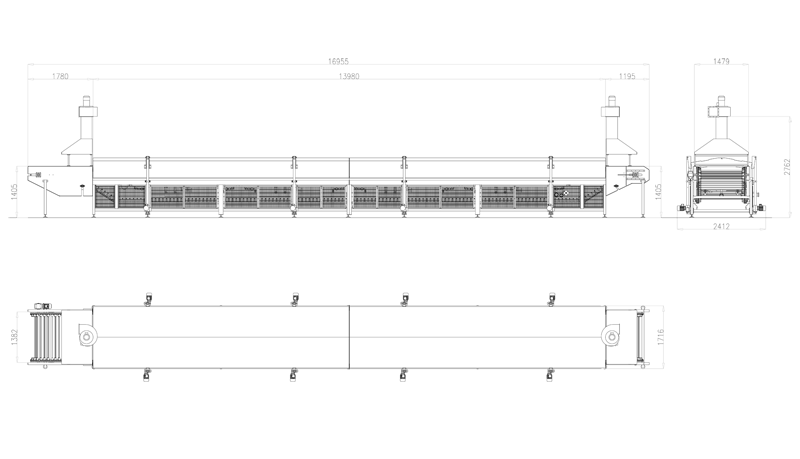

Cookers CCT series are the best solution for continuously cooking the dough in ready-meals lines. They guarantee uniformity of cooking, attention to transport operation and in-out phases of the product. These cookers are suitable for treating any dough dimensions and enable several cooking times.

Play the video

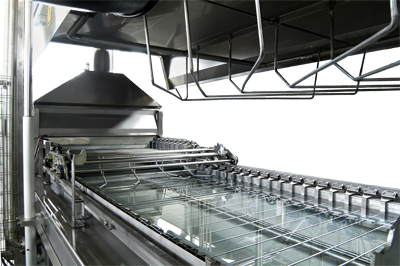

Moving rods system

Cooking basin totally accessible for an easy cleaning

Preventing damages caused by the starches produced during cooking

Optimization of the heat exchange

No side skidding of the dough

Stainless steel parts suitable for food contact.

The moving higher rods are inclined instead of transverse and keep the dough under the cooking water, avoiding friction damages: they can be easily lifted for cleaning.

Heating water system by heat exchanging single plates, placed in the lower panel of the basin: it is thus guaranteed a high level of thermal exchange.

Equipped with steam injection system with several inlets to avoid water condensation in the hard-to-reach parts of the cooker.

The cooking water level reaches the higher edge and brims over, enabling a regular discharge of the cooking starches on the surface along the whole perimeter of the cooker.

Stainless steel dividers to separate the entry of the cooking basin and prevent any steam leaks in the production area.

No need of a sanitary filter of the steam since the last one does not get in contact with the process water.

This article, appeared on Storcicom XVII, explains the technical details and the advantages of the cookers CCT series.