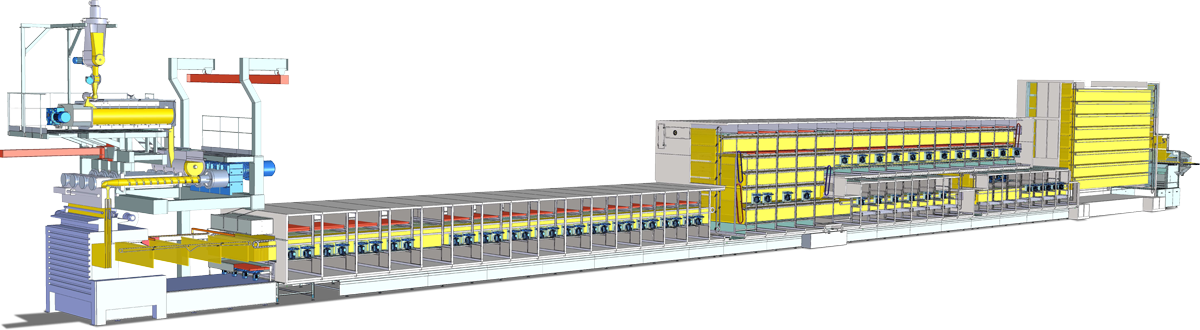

ITRG Functional diagram

The ITRG drying line features all the most important innovations in the treatment of long-cut pasta products. It is combined with a press, which has a dough mixing system that can be one of the following: Total Vacuum, Stabilization Belt or Traditional Mixer, a spreader, with 1 to 6 sticks depending on the capacity of the line, and a rapid cooler. The constructive and technological characteristics of this line allow to obtain optimal drying diagrams for each and every raw material used.

After a relatively intense predrying phase, a rather quick drying curve of about 2 h 40 min. is applied. During the drying process, the product undergoes a treatment which we call thermal inversion, that is, the pasta reaches its maximum temperature in a very short time and is then quickly lowered. The next drying phase is the stabilization phase which represents the equilibrium point of the entire system since it brings the product to a uniform final moisture content of 12.5% in a self-stabilizing area.

The gradual cooling phase prepares the pasta for the final cooling phase in an absolutely stable condition with the necessary surface humidification for dealing with the thermal impact caused by the considerable drop in temperature.

In the main drying and stabilizing body of the dryer, a stick rack mechanism is applied. The rack system does not require lubrication. The separate mechanical control in the different predrying, drying and cooling phases guarantee maximum operational flexibility during production transits or emergencies, reducing production losses to a minimum.

The sophisticated supervision system is intuitive and easy to use and ensures that you can run the line and all production cycle phases in a flexible and reliable manner. It integrates perfectly with the pasta factory control system to guarantee the exchange of all process data necessary for production control and product traceability.

| Capacity Kg/h | Press | Spreader | Dryer | Silo storage with stripper (i) |

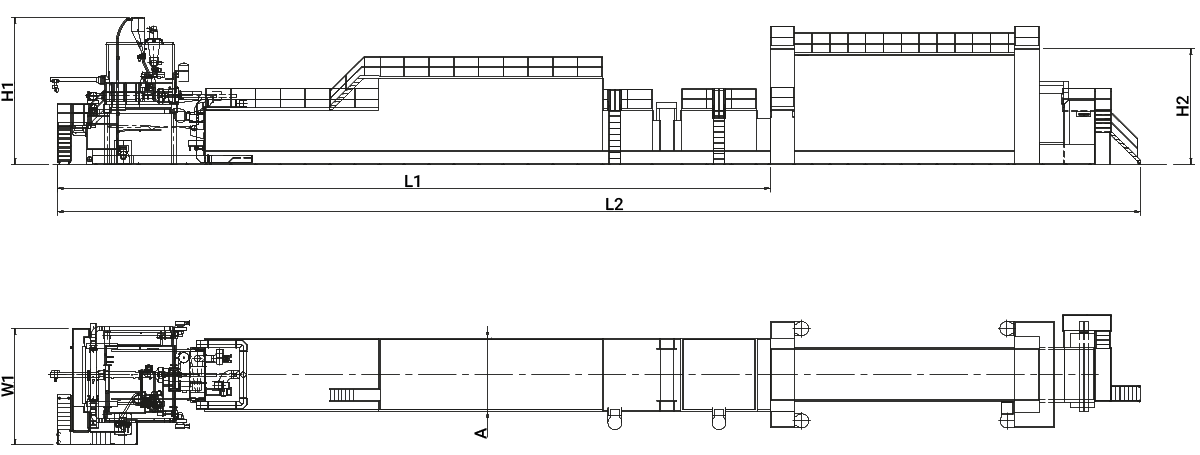

L2 mm | L2 mm | H1 mm | H2 mm | A mm |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | FA.ST. 180.1-2000 | STE-2/2000 | GPL/ITRG-A/10.0 | 2T 3T |

6p/9,5 m 1p/4 m |

1 IPACK 1 IPACK |

25000 25000 |

39750 33500 |

7000 7000 |

4970 3300 |

3170 3170 |

| 1500 | FA.ST. 200.1-2550 | STE-2/2550 | GPL/ITRG-AB/15.0 | 2T 3T |

6p/11,5 m 1p/6 m |

1 IPACK 1 IPACK |

32850 32850 |

49600 43350 |

7500 7500 |

5225 3300 |

3740 3740 |

| 2000 | FA.ST. 225.1-2550 | STE-2/2550 | GPL/ITRG-B/20.0 | 2T 3T |

7p/13,5 m 1p/8 m |

1 IPACK 1 IPACK |

36000 36000 |

54700 36000 |

7500 7500 |

5900 3300 |

3740 3740 |

| 3000 | FA.ST. 210.2-2550 | STE-3/2550 | GPL/ITRG-C/30.0 | 2T 3T |

7p/19,5 m 5p/7,5 m |

1 IPACK 1 IPACK |

42150 42150 |

66700 54700 |

9200 9200 |

5750 3750 |

3860 3860 |

| 3500 | FA.ST. 210.2-2550 | STE-4/2550 | GPL/ITRG-CD/35.0 | 2T 3T |

8p/19,5 m 6p/7,5 m |

1 IPACK 1 IPACK |

46658 46658 |

71309 59369 |

10118 10118 |

6400 4970 |

3860 3860 |

| 4000 | FA.ST. 225.2-2550 | STE-4/2550 | GPL/ITRG-D/40.0 | 2T 3T |

8p/21,5 m 5p/9,5 m |

2 IPACK 1 IPACK |

47500 47500 |

74000 62000 |

10300 10300 |

6400 4450 |

3860 3860 |

| 4500 | FA.ST. 245.2-2550 | STE-4/2550 | GPL/ITRG-DE/45.0 | 2T 3T |

8p/21,5 m 6p/9,5 m |

2 IPACK 1 IPACK |

51926 51926 |

81867 67927 |

9829 9829 |

7100 4450 |

3860 3860 |

| 5000 | FA.ST. 245.2-2550 | STE-5/2550 | GPL/ITRG-E/50.0 | 2T 3T |

9p/21,5 m 7p/15,5 m |

2 IPACK 2 IPACK |

54000 54000 |

84000 76000 |

11000 11000 |

7200 5750 |

3860 3860 |

| 5500 | FA.ST. 200.4-2550 | STE-5/2550 | GPL/ITRG-EF/55.0 | 2T 3T |

10p/21,5 m 7p/15,5 m |

2 IPACK 2 IPACK |

60548 60548 |

88489 82519 |

10838 10838 |

7100 5750 |

3860 3860 |

+39 051 68 43 411