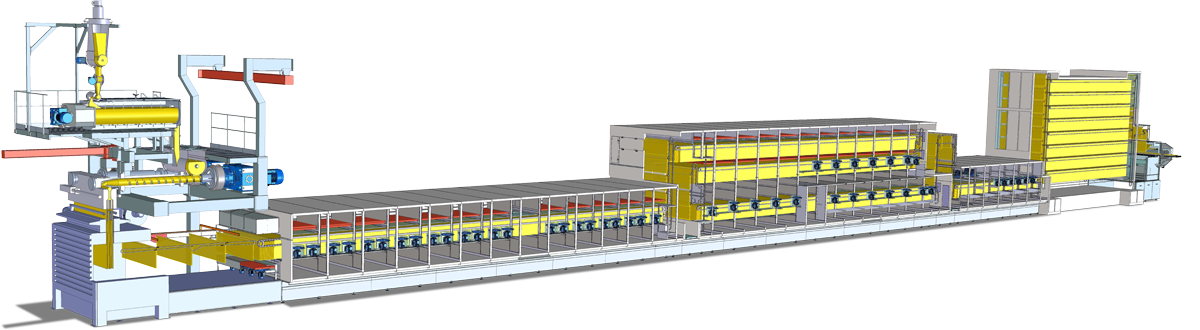

GPL 180 Functional diagram

The GPL 180 drying line represents the apex of technological evolution in the field of long-cut pasta drying. This line was designed to improve and optimize the drying process through innovative and patented technology and mechanics. As a result, maintenance operations have also been simplified. The constructive and technological characteristics of this line allow to obtain optimal drying diagrams for each and every raw material used.

It is combined with a press, which has a dough mixing system that can be one of the following: Total Vacuum, Stabilization Belt or Traditional Mixer, a spreader, with 1 to 6 sticks depending on the capacity of the line, and a rapid cooler.

The 180 minute drying time is obtainable through the implementation of a patented technology, specially designed and fine-tuned by Fava over the last number of years. This technology enables you to obtain a top quality finished product without stressing the pasta during the predrying and drying processes, which are very similar to the ones typical of the well-known ITRG lines, produced by us and highly appreciated throughout the world.

The colour of the pasta is brighter with equivalent cooking quality, mechanically resistant and very flexible making it easy to package. Totally designed with 3D CAD systems, the line was designed with modular and functional construction criteria and each detail has been studied to perform structural and practical functions, consequently limiting the number of components and facilitating maintenance operations in the pasta factory. It features a totally innovative kinematic motion mechanism for the stick chain drive. In fact, it allows to keep an independent motion in the different environments, a classical characteristic of the Fava lines, crucial to technological management during shape changeover or emergencies, while ensuring, at the same time, the continuous operation of the line through a patented self-adjusting motion system based on simple and reliable mechanics that limits stress on the mechanical components.

As regards energy consumption, given that the machine is smaller and does not use steam, compared to conventional technologies of the same production capacities a lower level of energy consumption is registered.

This line is completed with a very powerful cooler with a lateral ventilation system to prepare the pasta for the next step of storage or packaging.

The innovative electronic supervision system is easy to use and ensures that you can run the line and all production cycle phases in a flexible and reliable manner. It integrates perfectly with the pasta factory control system to guarantee the exchange of all process data necessary for production control and product traceability.

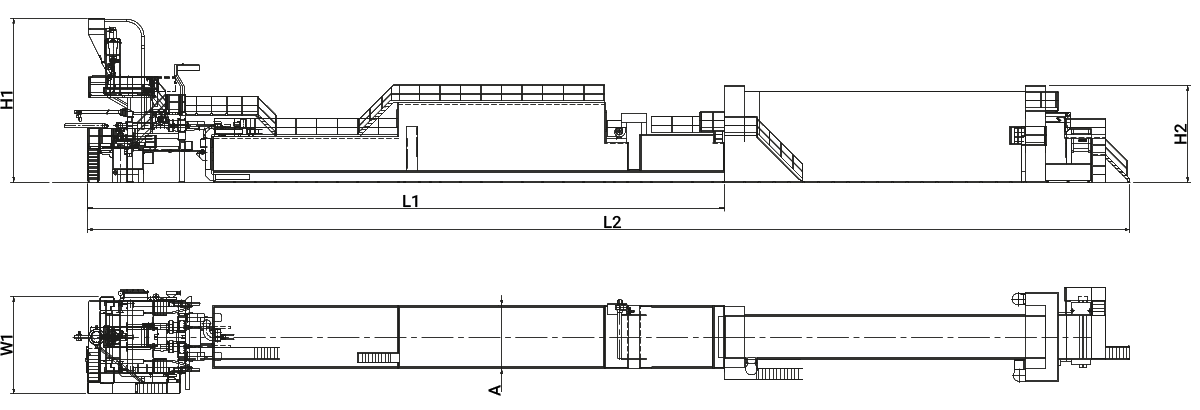

| Capacity Kg/h | Press | Spreader | Dryer | Silo storage with stripper (i) | L1 mm | L2 mm | H1 mm | H2 mm | A | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3000 | FA.ST. 210.2-2550 | STE-3/2550 | GPL/180- C/30.0 | 2T 3T |

7P/19,5 m 5p/7,5 m |

1 IPACK 1 IPACK |

38750 38750 |

63400 51400 |

10000 10000 |

5900 5180 |

3860 3860 |

| 3500 | FA.ST. 210.2-2550 | STE-4/2550 | GPL/180-CD/35.0 | 2T 3T |

8P/19,5 m 5p/7,5 m |

1 IPACK 1 IPACK |

44016 44016 |

68702 56762 |

9421 9421 |

5900 5180 |

3860 3860 |

| 4000 | FA.ST. 225.2-2550 | STE-4/2550 | GPL/180-D/40.0 | 2T 3T |

8p/21,5 m 5p/9,5 m |

2 IPACK 1 IPACK |

47200 47200 |

75200 63200 |

10000 10000 |

6500 4500 |

3860 3860 |

| 4500 | FA.ST. 245.2-2550 | STE-4/2550 | GPL/180-DE/45.0 | 2T 3T |

8p/21,5 m 6p/9,5 m |

2 IPACK 1 IPACK |

49724 49724 |

76855 64915 |

10577 10577 |

6500 4500 |

3860 3860 |

| 5000 | FA.ST. 245.2-2550 | STE-5/2550 | GPL/180-E/50.0 | 2T 3T |

9P/21,5 M 7P/15,5 M |

2 IPACK 2 IPACK |

56000 56000 |

84000 78000 |

10000 10000 |

7200 5900 |

3860 3860 |

| 6000 | FA.ST. 210.4-2550 | STE-6/2550 | GPL/180-F/60.0 | 2T 3T |

- 8p/15,5 m |

- 2 IPACK |

- 67300 |

- 89200 |

- 11900 |

- 6500 |

- 3860 |

+39 051 68 43 411