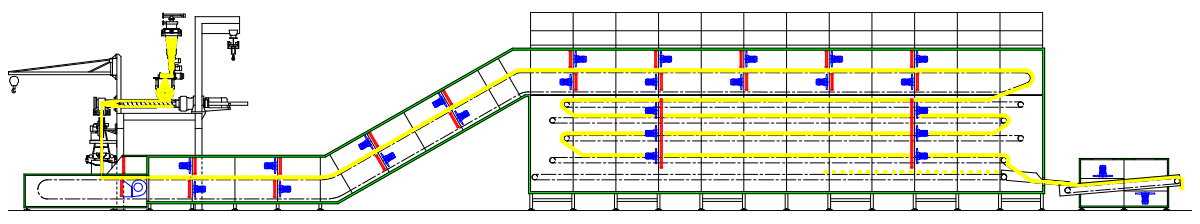

CTA functional diagram

The CTA drying line represents a highly innovative solution for producing and drying nests in cups. A specially designed nest forming machine, suitable for high-capacity lines, deposits extruded or laminated nests in cups in a sequential manner. This system ensures that the nests are deposited in perfect synchronization and that the cups move smoothly and continuously, reducing kinetic mechanical stress considerably. The design of this drying line was created to meet the needs of high capacity lines to be installed in very limited spaces in terms of length, by exploiting the height of the factories. The constructive and technological characteristics of this line allow to obtain ideal drying diagrams for each and every raw material used.

Like all the other lines, the CTA dryer is combined with a press, which has a dough mixing system that can be one of the following: Total Vacuum, Stabilization Belt or Traditional Mixer.

One of the strong points of this line is represented by its predryer which has a straight transit area and a sloped transit area in order to feed the dryer at a height. It is equipped with metal slats which contain the cups for the nests. The perfect airtight features is guaranteed by the same highly successful feature applied to our short goods dryers: the metal slats are fastened and driven by chains which ensure that any swinging movements are prevented. The geometric profile of the slat joints for linking them together makes sure that their coupling is airproof. This way, the air must only flow over the cups ensuring that the nest inside the cup is treated efficiently and uniformly. The first efficient predrying phase is followed by the drying and stabilizing phases, carried out in a dryer which features synthetic mesh belts on which the product is exposed to a very delicate technological treatment given the shape and fragility of the product in question. At the end of the dryer, there is a storage tier made of metal slats which acts as a temporary storage area should the packaging lines shutdown - the product is kept in this phase in stabilized climatic conditions.

A very clever emptying system, managed directly from the supervision system, allows you to gradually empty the storage tier when the packaging lines start up again without interfering with the production cycle, avoiding any unnecessary downtime.

At the end of the dryer, the product is transferred to a cooler on synthetic mesh belts. The air which can be cooled naturally or by means of cold water coils, flows over the product, according to a maximum efficiency logic which guarantees that nests are cooled in an efficient and uniform manner. This way, the nests are optimally prepared and ready for the packaging phase.

The innovative electronic supervision system is intuitive and easy to use and ensures that you can run the line and all the production cycle phases in a flexible and reliable manner. It integrates perfectly with the pasta factory control system to guarantee the exchange of all process data necessary for production control and product traceability.

| Capacity Kg/h | Press | Nest Machine | Model CTA | L mm |

|---|---|---|---|---|

| 400 | FA.ST. 145.1-2000 | SD 24/65 | GN-CTA 12/4 | 30500 |

| 700 | FA.ST. 160.1-2000 | SD 24/65 | GN-CTA 15/5 | 32500 |

| 1000 | FA.ST. 180.1-2000 | DD 24/65 | GN-CTA 18/5 | 37500 |

+39 051 68 43 411